Global Finishing Solutions

About GFS

A vertical manufacturer, Global Finishing Solutions® (GFS) has an extensive history of designing and building exceptional paint booths and finishing equipment that help businesses achieve flawless paint finishes, maximize productivity and protect the health of their employees. Our high-quality, proven products are backed by our unmatched technical support team, distribution network and field services staff for lifelong support of your spray booths and finishing equipment.

Read more from GFS >

A vertical manufacturer, Global Finishing Solutions® (GFS) has an extensive history of designing and building exceptional paint booths and finishing equipment that help businesses achieve flawless paint finishes, maximize productivity and protect the health of their employees. Our high-quality, proven products are backed by our unmatched technical support team, distribution network and field services staff for lifelong support of your spray booths and finishing equipment.

Read more from GFS >

|

|

Products

Combining advanced technology, high-quality components and excellent support, Global Finishing Solutions provides industry-leading spray booths and finishing equipment for a wide variety of industries — including aerospace, automotive refinish and industrial manufacturing. Our spray booths and finishing equipment are expertly designed for superior performance and longevity. We build almost all of the components of our products, including the lights, fans, motors, control panels, filters and the enclosures themselves, at our facility in Osseo, Wisconsin. |

Spray Booths and Finishing Systems For All Applications

Global Finishing Solutions® (GFS) is dedicated to providing the most efficient, high-quality and ecologically friendly spray booths and finishing environments for the aerospace, automotive refinish and industrial finishing industries, among others. Headquartered in Osseo, Wisconsin, GFS has an extensive history of providing businesses with exceptional finishing equipment and services that allow them to achieve flawless finishes and maximize productivity.

Global Finishing Solutions® (GFS) is dedicated to providing the most efficient, high-quality and ecologically friendly spray booths and finishing environments for the aerospace, automotive refinish and industrial finishing industries, among others. Headquartered in Osseo, Wisconsin, GFS has an extensive history of providing businesses with exceptional finishing equipment and services that allow them to achieve flawless finishes and maximize productivity.

|

Performer Paint Booths

GFS’ Performer Paint Booth Line provides reliable, cost-effective solutions for painting automotive vehicles and parts. Designed for small and medium-sized shops, Performer Paint Booths feature quality construction, bright, color-corrected lighting, and effective overspray capture and contamination control for a reliable, all-in-one painting environment. Performer Booth models and standard options are fully ETL and ETL-C listed, ensuring that the entire booth complies with applicable safety codes and meets performance requirements. ETL listing facilitates successful inspections and demonstrates that Performer Booths have completed independent, third-party review. |

|

Ultra Paint Booths

With exceptional lighting, intuitive controls, premium contamination control and effective overspray capture, high-performance Ultra Paint Booths from Global Finishing Solutions allow for flawless paint finishes and increased productivity. Pre-engineered Ultra Paint Booth models and standard options are fully ETL and ETL-C listed, ensuring that the entire booth complies with applicable safety codes and meets performance requirements. ETL listing facilitates successful inspections and demonstrates that Ultra Booths have completed independent, third-party review. |

Edge Paint Booth is excellecence reimagined. The Edge™ Paint Booth from Global Finishing Solutions (GFS) provides industry-leading features with an updated, modern design, while being backed by a manufacturer with decades of experience in the automotive refinish industry. Masterfully designed for today’s collision repair centers and paint shops, this booth delivers advanced controls; precise, adjustable lighting; and premium contamination controls to consistently produce excellent paint finishes

and improved throughput.

and improved throughput.

EFFICIENCY EVERY STEP OF THE WAY: From top to bottom, GFS Edge is designed for efficiency. Standardized interior dimensions — pre-engineered at 27-, 30- and 33-foot lengths and 9- or 12-foot heights — mean the Edge Paint Booth can accommodate the ever-increasing size of vehicles today without the custom engineering that can prolong lead times. Once your new booth arrives on site, the flush panel design speeds up installation and makes cleaning the booth’s interior a breeze.

DIMMABLE LED LIGHTING: The GFS Edge Paint Booth comes standard with dimmable LED lighting. Light fixtures in Edge Paint Booths are strategically placed in the booth’s sidewalls and ceiling to minimize the appearance of shadows and hotspots on the vehicle’s surface, and painters can adjust the bulbs’ brightness while they are working. By diffusing light evenly, you can expect better quality paint jobs.

SLEEK PANELS & DOORS: Featuring flush, dual-skin construction for a smooth interior and exterior, and sporting a sleek new door design, this modernized booth is sure to be a showpiece in any shop. Product and personnel doors with large, inlaid glass panels provide an unobstructed view into the booth, while panic bars allow painters to exit the booth with full hands. Doors are designed to integrate with larger booth openings without any added weight, improving the hinge alignment and seal with less maintenance overall.

OPTIMIZE FLOOR SPACE: Flexible placement of GFS’ SpaceSaver Air Heater, which can be positioned either horizontally atop or vertically alongside the booth, maximizes airflow without increasing the overall product footprint the way other air heaters do. Additionally, SpaceSaver has a higher airflow rate than comparable air heater models, giving the Edge Paint Booth improved performance. Air moves into the booth through the proven Controlled Airflow Ceiling, in a downdraft or semi-downdraft configuration, producing excellent contamination control and even air distribution.

DIMMABLE LED LIGHTING: The GFS Edge Paint Booth comes standard with dimmable LED lighting. Light fixtures in Edge Paint Booths are strategically placed in the booth’s sidewalls and ceiling to minimize the appearance of shadows and hotspots on the vehicle’s surface, and painters can adjust the bulbs’ brightness while they are working. By diffusing light evenly, you can expect better quality paint jobs.

SLEEK PANELS & DOORS: Featuring flush, dual-skin construction for a smooth interior and exterior, and sporting a sleek new door design, this modernized booth is sure to be a showpiece in any shop. Product and personnel doors with large, inlaid glass panels provide an unobstructed view into the booth, while panic bars allow painters to exit the booth with full hands. Doors are designed to integrate with larger booth openings without any added weight, improving the hinge alignment and seal with less maintenance overall.

OPTIMIZE FLOOR SPACE: Flexible placement of GFS’ SpaceSaver Air Heater, which can be positioned either horizontally atop or vertically alongside the booth, maximizes airflow without increasing the overall product footprint the way other air heaters do. Additionally, SpaceSaver has a higher airflow rate than comparable air heater models, giving the Edge Paint Booth improved performance. Air moves into the booth through the proven Controlled Airflow Ceiling, in a downdraft or semi-downdraft configuration, producing excellent contamination control and even air distribution.

EASY TROUBLESHOOTING & OPERATION: The Edge Paint Booth’s easy-to-operate controls feature a large, 10-inch touch screen, with a 15-inch screen available as an upgrade. The improved user experience makes it easy to set up, run booth cycles and perform maintenance.

Navigation is simplified, with different modes based on your role and the tasks you need to complete, so the most relevant information and controls are always at the forefront of the HMI. GFS has also implemented independent toggles and start/stop buttons to avoid the hassle of paint getting on the touch screen.

Navigation is simplified, with different modes based on your role and the tasks you need to complete, so the most relevant information and controls are always at the forefront of the HMI. GFS has also implemented independent toggles and start/stop buttons to avoid the hassle of paint getting on the touch screen.

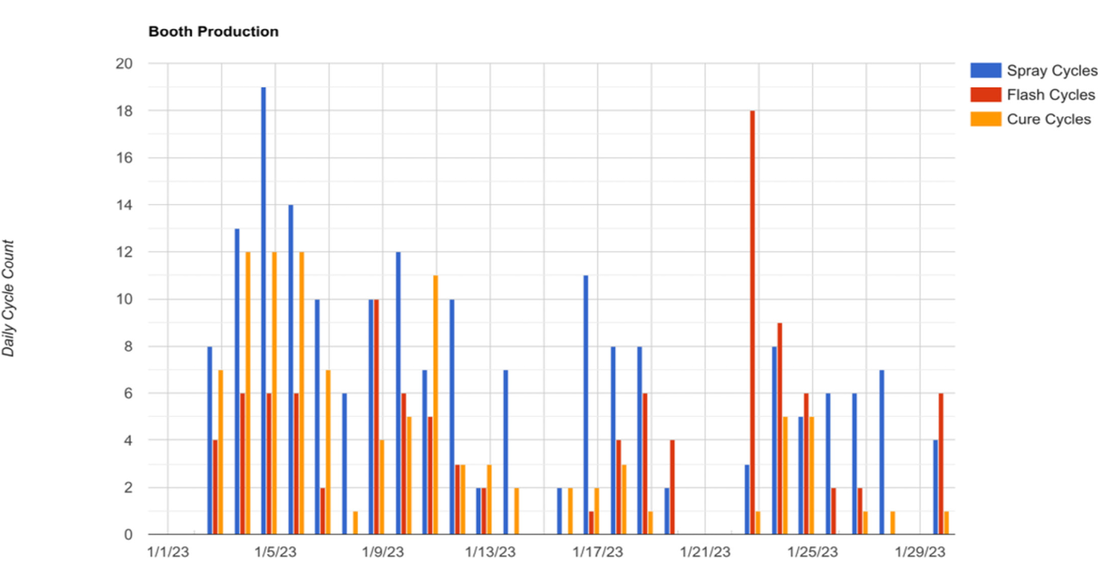

Booth Connect the remote booth monitoring system. Booth Connect from Global Finishing Solutions (GFS) provides remote access and monitoring for paint booths from the convenience of a computer, tablet or smartphone. This patent pending technology provides on-demand insight into booth cycles, filter loading and power usage trends, building a portfolio-level dashboard and KPIs.

SEAMLESS INTEGRATION: Booth Connect units offer enough flexibility to monitor booth pressure, filter loading and burner information for booths produced by GFS or any other major paint booth manufacturer. Additionally, an onsite server is not necessary because all booth data is stored securely in the Cloud.

REMOTE MONITORING: Get real-time visibility into a paint booth’s filter loading, production levels and usage data from anywhere and at any time. Booth Connect’s dashboards enable painters, paint shop managers, owners and corporate decision makers to view reports and track performance. These dashboards have the capability to consolidate information from individual paint booths all the way up to a company’s entire booth portfolio.

NOTIFICATIONS & ALARMS: Remote monitoring not only helps shops track cycles and gauge the power usage of their equipment, but Booth Connect can also send notifications if a paint booth enters an alarmed state or loses connectivity, ensuring efficiency and potentially protecting a business’ assets.

VALUABLE DATA AT YOUR FINGERTIPS: With the ability to monitor paint booths remotely, you always have the data you need to keep your business — and equipment — running at peak performance. Booth Connect’s operational insights help drive production efficiency by providing real-time, consolidated information on cycle counts, energy usage and other helpful measurements to empower management teams to track, monitor and ultimately improve shop efficiency and output.

EFFICIENCY & COST SAVINGS: By monitoring filter loading, shops can easily pinpoint the right time to change their paint booths’ filters — eliminating unnecessary downtime and potential damage to a booth’s ductwork or fans caused by delayed maintenance. Booth Connect also automatically logs filter changes, so shops no longer need to manually log and store filter test sheets to stay in compliance with the EPA’s 6H rule.

SEAMLESS INTEGRATION: Booth Connect units offer enough flexibility to monitor booth pressure, filter loading and burner information for booths produced by GFS or any other major paint booth manufacturer. Additionally, an onsite server is not necessary because all booth data is stored securely in the Cloud.

REMOTE MONITORING: Get real-time visibility into a paint booth’s filter loading, production levels and usage data from anywhere and at any time. Booth Connect’s dashboards enable painters, paint shop managers, owners and corporate decision makers to view reports and track performance. These dashboards have the capability to consolidate information from individual paint booths all the way up to a company’s entire booth portfolio.

NOTIFICATIONS & ALARMS: Remote monitoring not only helps shops track cycles and gauge the power usage of their equipment, but Booth Connect can also send notifications if a paint booth enters an alarmed state or loses connectivity, ensuring efficiency and potentially protecting a business’ assets.

VALUABLE DATA AT YOUR FINGERTIPS: With the ability to monitor paint booths remotely, you always have the data you need to keep your business — and equipment — running at peak performance. Booth Connect’s operational insights help drive production efficiency by providing real-time, consolidated information on cycle counts, energy usage and other helpful measurements to empower management teams to track, monitor and ultimately improve shop efficiency and output.

EFFICIENCY & COST SAVINGS: By monitoring filter loading, shops can easily pinpoint the right time to change their paint booths’ filters — eliminating unnecessary downtime and potential damage to a booth’s ductwork or fans caused by delayed maintenance. Booth Connect also automatically logs filter changes, so shops no longer need to manually log and store filter test sheets to stay in compliance with the EPA’s 6H rule.

|

AdvanceCure

Designed to help collision centers be more productive, efficient and profitable, the AdvanceCure Accelerated Airflow System from Global Finishing Solutions® (GFS) greatly reduces the amount of time needed to dry any type of base coat — be it waterborne or solvent-based. AdvanceCure distributes heat more evenly throughout the booth and over the vehicle. By reducing the amount of time required for each paint job and promoting an even cure in less time, AdvanceCure helps put more jobs through your shop. |

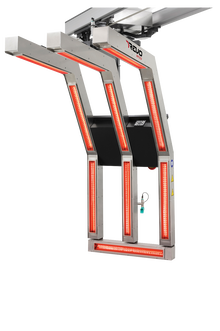

Revo Accelerated Curing Systems Improve your paint shop efficiency without having to overhaul your space with REVO Accelerated Curing Systems from Global Finishing Solutions. The revolutionary technology cures filler and coatings quickly from the inside out, offering the fastest curing time in the industry for both prep and paint processes.

Easy to operate and install, REVO Systems save time and improve results. With multiple models designed to fit a variety of needs, there’s a solution to start saving you time and money immediately. Repair cycle time is shortened and rework is significantly reduced thanks to the high quality, complete cure REVO Systems always deliver.

Read more about Revo from GFS >

Easy to operate and install, REVO Systems save time and improve results. With multiple models designed to fit a variety of needs, there’s a solution to start saving you time and money immediately. Repair cycle time is shortened and rework is significantly reduced thanks to the high quality, complete cure REVO Systems always deliver.

Read more about Revo from GFS >

|

Revo Rapid

Quickly cure filler and coatings with the REVO Rapid. Producing high-quality repairs, this compact, two-cassette system is designed for full panel repairs or body shops with space restrictions. REVO Rapid is perfect for smaller, quick repair jobs of one to two panels, and can reach any part of a vehicle. Safely and efficiently cure coatings on two different panels simultaneously, while maintaining the correct temperature. REVO Rapid is ideal in prep areas and GFS’ Closed-Top Open-Front (CTOF) Booths. Choose from an overhead rail system (OR2) or mobile system on wheels (MC2). |

|

Revo Speed

Dramatically reduce curing time with the REVO Speed. This fast-positioning model is best suited for collision repair facilities with speed lanes for repairs on one to four panels. With a vehicle clearance of 7 feet, the REVO Speed can accommodate all sizes of passenger vehicles, including cars, trucks, minivans and SUVs, as well as factory lifted trucks. |

Revo Handheld

Rapidly cure filler and coatings in three minutes or less with the REVO Handheld. This powerful, lightweight tool is ideal for fast plastic repairs, but can also be used in every step of the repair process. With the REVO Handheld, you can repair small areas, soften glass seals, heat aluminum to repair aluminum-body vehicles, as well as remove dents, emblems, vinyl graphics and adhesives. The REVO Handheld allows you to get more repairs done faster, saving you time and money.

Rapidly cure filler and coatings in three minutes or less with the REVO Handheld. This powerful, lightweight tool is ideal for fast plastic repairs, but can also be used in every step of the repair process. With the REVO Handheld, you can repair small areas, soften glass seals, heat aluminum to repair aluminum-body vehicles, as well as remove dents, emblems, vinyl graphics and adhesives. The REVO Handheld allows you to get more repairs done faster, saving you time and money.